Find Bad Panels

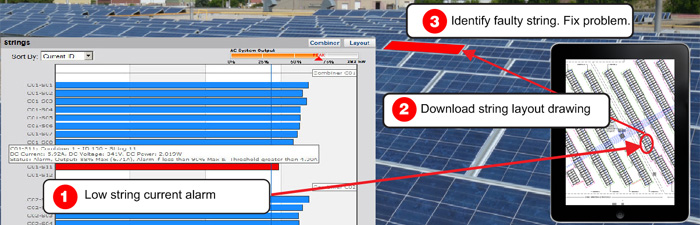

A single bad panel reduces the string output leading to lost revenue if not detected. Install smart combiner boxes to compare every string and create an alarm if one string is significantly below the others. Maintenance staff can download a string layout saved from the original design drawings. Locate the string location from the displayed ID and drawing orientation. Quickly identify and fix the problem cause. Verify the string returns to full normal output before leaving the site.

Eliminate guesswork saving troubleshooting time on a roof with hundreds of panels. A wireless tablet at the site helps an EPC speed up commissioning and customer signoff by demonstrating that every string is working properly. The smart combiner peak recorder saves the maximum output current with a timestamp showing if panels reach their rated output under all conditions of irradiance and temperature.

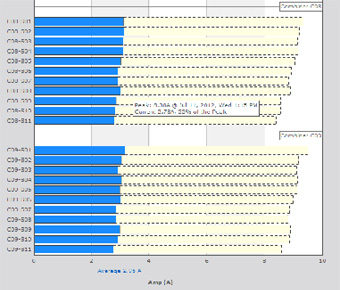

Check Output to Specifications

Assessing whether panels meet their published specifications under real-world conditions can be challenging due to constant fluctuations in irradiance and temperature. The smart combiner's peak recorder simplifies this by capturing the maximum output current, along with a timestamp, to show when panels achieve their rated output. You can reset the peak recorder anytime to begin a new measurement interval.

To compare current output (blue) with peak output (yellow), select the 'Current Peak ID' in the 'Sort by' menu. This allows you to quickly check if the peak output of each string matches the specified rating, making it easy to identify any underperforming panels.

Reduce Inspection Costs

Use the smart combiner feature to monitor each string's output under varying weather conditions, ensuring every string consistently meets its expected output and reducing the need for costly, periodic manual current checks.

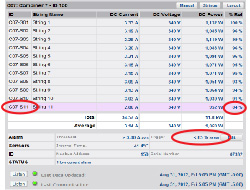

Two red lines indicate that strings I16-S01 and I16-S02 are at 0% and N/A of maximum output, falling below the user-defined alarm threshold of 35%. If enabled, this triggers an email alert, helping identify issues that on-site equipment may not flag as fault conditions. Download the layout drawing for quick identification and resolution of the issue.